by bassybeats | Aug 22, 2021 | Retro Gaming

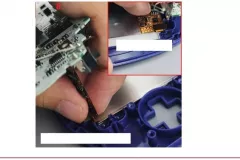

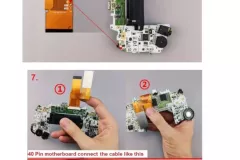

Just a short one this time. I picked up a cheap Gameboy Advance but instantly realised how awful the screens were, something that I wasn’t aware of as I had always had PSP’s. But a quick search on AliExpress surfaced this upgrade kit which was exactly what I was after. This instructions were non-existent, even though the seller said they would send them afterwards I never got anything.

Luckily the kit was good and I could just reference the photos on the listing to figure out what parts of the plastic to cut out. I opted to leave out the brightness mod and have it full brightness all the time.

by bassybeats | Aug 21, 2021 | Computing

As part of my want to recreate some of my earliest machines growing up I thought I would go back to the very first one, a 486. It was a hand me down desktop style with Windows 95 on it. I don’t think I had it long before I upgraded to a Pentium 100/120.

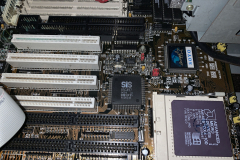

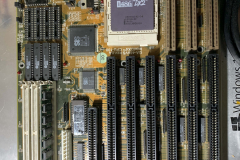

Retro collection day pickup

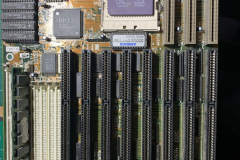

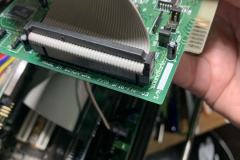

It wasn’t really going to be a reality until I saw a pair of machines at the retro tech sale in Onehunga just before the very first covid lockdown. Sadly I couldn’t open them up properly to look inside other than seeing they had 486 chips inside. Once I got them home as well as some ram I could open them up and see the horror that awaited me. Both boards had bad battery damage and were completely non functional, at least the cases, power supplies, floppy drives and expansion cards were all in working order. Lucky for me, one of my fellow retro gamers had found some 486 boards at the same sale that he gifted me to get me up and running with a 486, as well as a VLB video card.

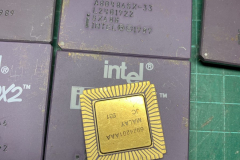

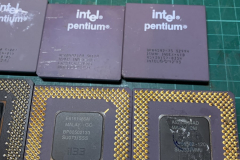

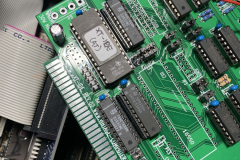

Bulk chip pickup

As a bit of a fluke purchase I spotted a listing for 3kg’s of CPU’s. Everything from Pentiums, 486’s, Pentium Overdrives and more. A lot of the chips had bent pins as they had clearly been sitting in a box/bin for years. It wasn’t overly cheap but I managed to remove some of the double ups and get all my money back, essentially making my ones free. These chips will give me a good base to test from.

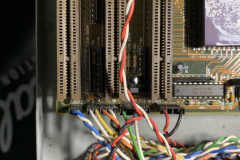

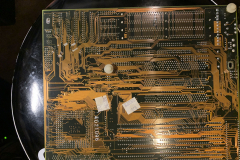

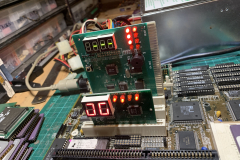

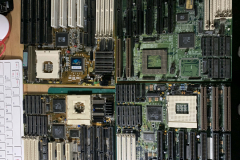

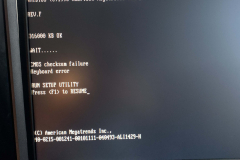

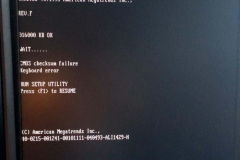

Round 1 of repairs

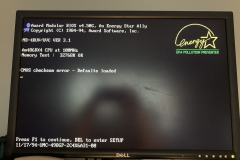

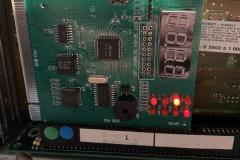

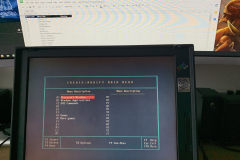

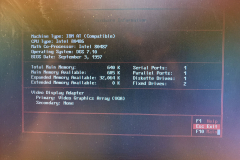

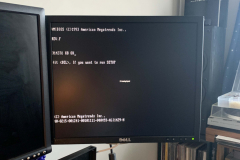

The first round of testing went so so. A lot of the boards that I had were battery damaged. One of the the hardest parts of diagnosing these boards was actually finding the manuals to get the jumper settings for each board. Some of them I just couldn’t find anything on them so I had to resort to putting a less ideal chip in them to see if I got any post codes come up, if only to get a model number or something to be able to look up. I did managed to get 4 boards going on this round.

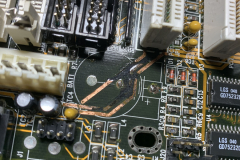

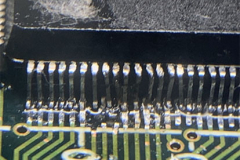

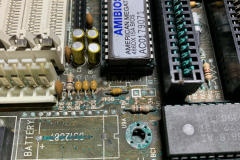

Chip damaged

I did manage to track down a fairly unusual issue. Upon closer inspection of one of the boards I was given from my mate, the main chip was actually not connected to the board at all, and on even closer inspection, it looked like it had been hit but something and bent a few pins/ripped some traces. I did attempt to reconnect these pins but had no success getting the board to work.

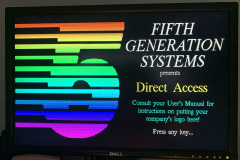

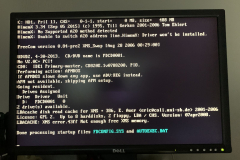

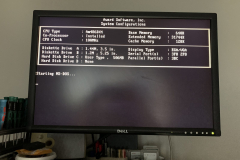

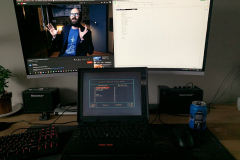

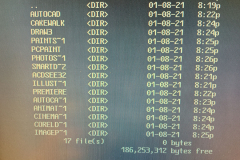

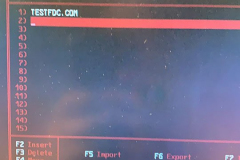

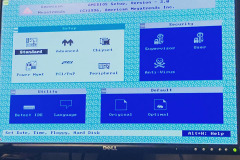

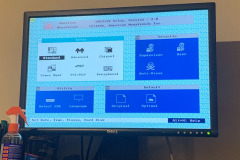

DOS Setup

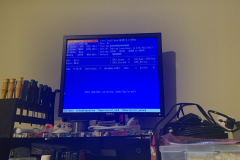

Once I had two boards working for the two cases I picked up I loaded up my DOS image and got everything working.

Repairs Round 2

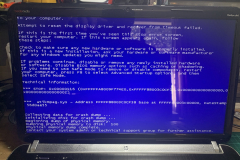

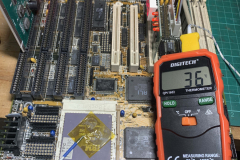

About 8 months after a few other projects I decided to revisit the boards and see if I had learnt anything and if I could get any more going, or at a minimum get rid of the ones that I couldn’t get working. Turns out I did learn something. Out of this batch I managed to get 5 boards going. Some of the issues I had were:

- no power on some of the rails ( bad solder joints )

- wrong ram used ( more on that below )

- Finding a CPU that worked with the board. I found that the IBM DX2 ( Cyrix chip ) seemed to be the most compatible for some reason. Once I got it booted I could then take note of the board/bios to do more googling

- bad keyboard chip

- Missing traces that I missed the first time around. This time I had a digital microscope to be able to get a much better look at the damaged traces.

- corroded pins on bios and other chips which I fixed by tinning them with solder.

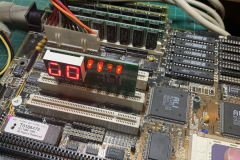

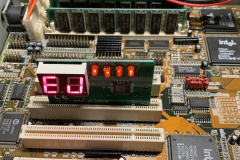

So it was a good second round of repairs. Sadly I still had 3 boards that showed no signs of life. They all showed power, and the bios read good but the reset line just stayed high and the post code reader showed 00. Something that I found out this time around was that the 4 digit post code readers actually are just two 2 digit readers, with the ones on the left being the current code and the ones on the right being the previous code. This made diagnosing it much easier as I could actually look up the code and know what the issue was ( like things in the 80’s being keyboard related and low error code being ram issues ).

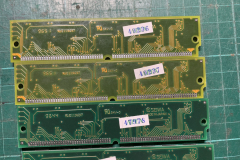

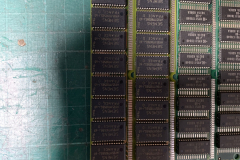

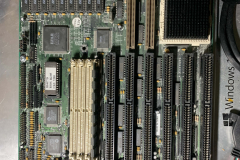

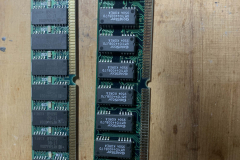

Ram Discovery

One likely obvious thing I discovered this time around which was likely a big part of the success was that there is actually two types of 72pin SIMMS. EDO and FPM and that ‘most’ 486 boards only support FPM modules. Even externally they are not easy to tell apart but I saw something on a forum that if the part number of the chips ends a 0 (zero) it will likely be FPM and if it ends in a letter it will likely be EDO, something that checked out for all the modules that I had. I had no luck with the 30pin modules, which was likely a jumper issue and a lack of manuals available.

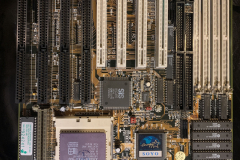

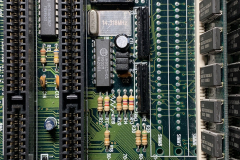

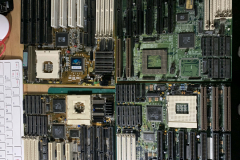

Final working boards and machines

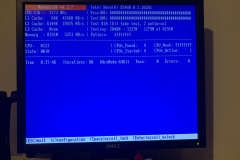

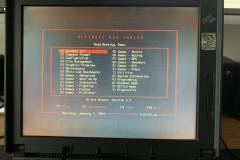

So out of the full set of 10 boards I ended up with 7 that work in some way or another, my base level is, if it posts to a bios screen I consider it a success for now. The 7 boards are:

- A Gigabyte GA-486VS with an Intel DX2-50, 16MB of ram and 256k of cache

- An MB-8433UTC PCI board with an AMD DX4-100, 32MB ram and 256k of cache

- An unknown OPTI chip board with a DX4-100, 16mb of ram and 256k of cache

- An HD4077D board with an Intel 486 DX2-66, 8mb of ram and 256k of cache

- An AL 486 board with a DX4-100, 64mb of ram and 256k of cache

- An unknown ALI M428/M431 based board with an IBM Lightning DX2-50, 16MB ram, no cache and still has a keyboard detection error

- An MB-4DUVC-P-AB board with a DX4-100, 64mb of ram, 256k of cache

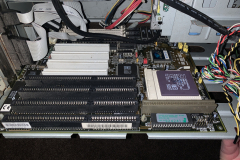

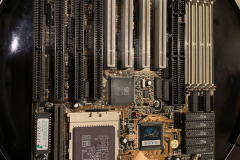

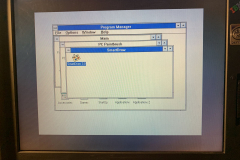

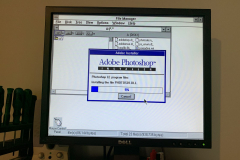

The two full machines are both loaded with my DOS Image:

- The small tower with the MB-4DUVC-P-AB board, DX4-100, 64mb of ram, 256k of cache, Creative Vibra 16 ( with CD Drive on the IDE header ), Dual Compact Flash to IDE adapters, I/O card,1.44mb 3.5″ floppy, 1.2mb 5.25″ floppy, and a Western Digital WDC WD90C33-22 VLB video card

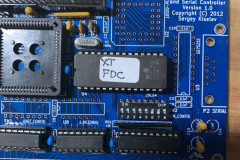

- The desktop with the MB-8433UTC PCI board, AMD DX4-100, 32MB ram, 256k of cache Soundforge Vibra 16S, ISA Floppy Disk Controller by Sergey Kiselev, 1.44mb 3.5″ floppy, XT-IDE Rev 2 board and a S3 Virge Trio64+ PCI video card.

Final non-working machines

As for the non working boards, I actually got one of them working in the photo, so I am left with two PCI boards and another MB-4DUVC-P-AB with the bent pins/traces. These showed no signs of life and with 7 others I figured i’d move past them and onto other projects.

by bassybeats | Apr 10, 2021 | 3D Printing

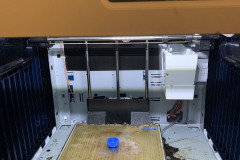

After visiting my friend for a few times and seeing this old XYZ Da Vinci sitting on the ground I said to him that I would take it off his hands and try and get it going. He said he had it for a few years and never got it to work, but since I had recent good success with my Makerbot I figured I would give it a crack for him. Turns out it was in worse shape than I expected, although it turned on it would not connect to the standard XYZ software ( which sucks btw and you need to create an account to even use it ).

Luckily, it get it to print something there was a sample print stored on the internal SD card which was enough to test it out. Leveling it was nightmare and I ended up doing it manually by turning off the machine just as it goes to print and then using a 0.08mm feeler gauge on the glass bed as the auto leveling kept failing.

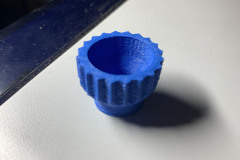

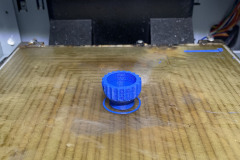

First Prints

The first prints actually worked! There was still a really bad adhesion issue and I had to use a glue stick on the heated bed to get it to stick at all, but at least I could rule out the extruder and printing side of it, leaving it to a leveling and heated bed issue. The print quality was pretty low from the stock sample prints was it was enough to prove the machine could still actually print.

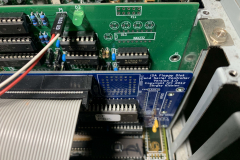

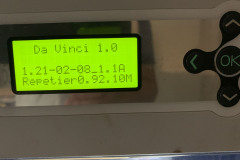

Firmware Flash

Now to get the machine to talk to the PC. I opted to follow the Repetier Firmware for DaVinci printers. Its a custom firmware that allows you to other software and slicers with the machine and fixes a bunch of issues. The guide to installing it is here so I won’t go into detail on what I did other than pointing out a couple of gotchas I ran into. You absolutely need the Arduino 1.8.0 IDE to get this to work, step 4 won’t work with out it. And make sure you set the code configuration.h file, I got black bars the first time around.

After this I downloaded Repetier Host and managed to connect to the printer! I also found a bunch of profiles online that i will link at the bottom. For the record, I also got Simplify 3D to work with this machine if that is what you are using, which has profiles built into it.

Bed Levels

After getting to this point I was still not having luck getting prints to stick to the bed, I manually leveled the bed multiple times ( the custom firmware has more spot to level from ), it wasn’t until the 6th time i was doing it that I realised that the glass bed was warped, all 4 corners were higher than the centre, revealing the problem. So this is where i stopped and said to my mate that he’s best to look out for a heated bed replacement or attempt to repair it

Downloads and Links

by bassybeats | Apr 10, 2021 | Others

This project isn’t specifically a build project, but it is something that I have wanted to put together for a long time. When I was in Nepal I picked up a small “legit” Northface mini pack as I thought it would be good for first aid kit, something that I have never had other than the crappy ones you get from the pharmacy. Its a pretty basic kit that I will keep in my car. The concept was to have everything I would need if I came off my mountain bike in the forest.

Contents

- Sling

- finger splint

- Various painkillers

- antiseptic wet wipes

- hand sanitiser

- chap stick

- ear plugs

- anti antihistamine and anti fungal creams

- a travel first aid kit with bandages, plasters, gauze etc

- face mask

- scissors

- paracord

- zip ties and electrical tape and lighter

- paying cards

- leg maglite

- pencil and notebook

- knife and scalpel

by bassybeats | Apr 4, 2021 | Computing

$20 pickup

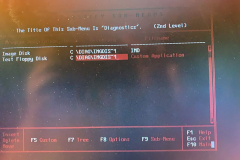

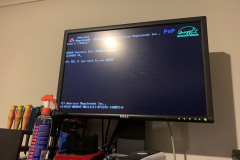

After an awesome find on Facebook marketplace I came home with a Pentium 2 and Pentium Pro machine. Both had their issues. This one had a bad bios battery and a dead VRM board, something that wasn’t apparent right away. The machine actually booted up at first until it released the white smoke.

VRM board dead

Turns out one of the capacitors on the VRM board decided to explode and take the PCB with it. I suspect that the cap leaked and shorted both layers and burnt a hole through it. Once I cleaned it out and found new copper to put the new caps.

After the new caps were in, the machine booted right up. Only to get stuck at the bios screen. It turns out this particular bios needs a working bios battery to get into Windows/DOS. To make it worse, it uses a clock chip with a built in battery. Something not easily available, but AliExpress came to the rescue.

I actually ended up giving this machine to my dad as I was more after a 486 machine and just don’t have the space.

Recent Comments