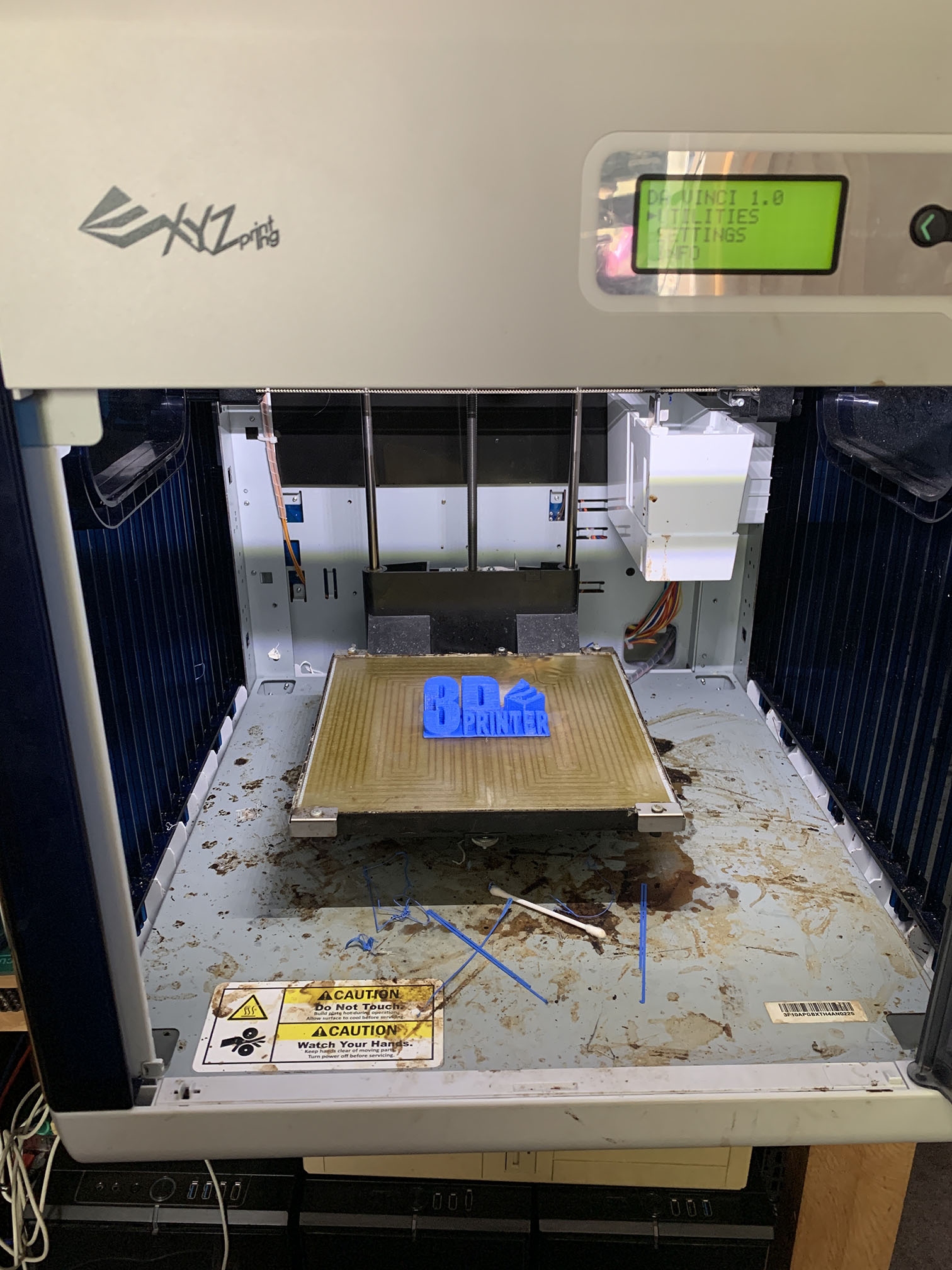

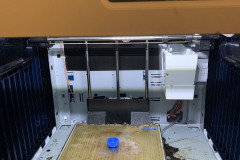

After visiting my friend for a few times and seeing this old XYZ Da Vinci sitting on the ground I said to him that I would take it off his hands and try and get it going. He said he had it for a few years and never got it to work, but since I had recent good success with my Makerbot I figured I would give it a crack for him. Turns out it was in worse shape than I expected, although it turned on it would not connect to the standard XYZ software ( which sucks btw and you need to create an account to even use it ).

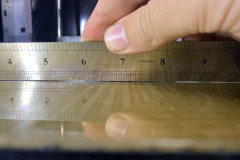

Luckily, it get it to print something there was a sample print stored on the internal SD card which was enough to test it out. Leveling it was nightmare and I ended up doing it manually by turning off the machine just as it goes to print and then using a 0.08mm feeler gauge on the glass bed as the auto leveling kept failing.

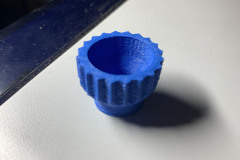

First Prints

The first prints actually worked! There was still a really bad adhesion issue and I had to use a glue stick on the heated bed to get it to stick at all, but at least I could rule out the extruder and printing side of it, leaving it to a leveling and heated bed issue. The print quality was pretty low from the stock sample prints was it was enough to prove the machine could still actually print.

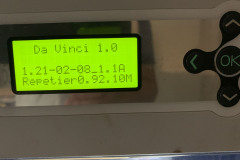

Firmware Flash

Now to get the machine to talk to the PC. I opted to follow the Repetier Firmware for DaVinci printers. Its a custom firmware that allows you to other software and slicers with the machine and fixes a bunch of issues. The guide to installing it is here so I won’t go into detail on what I did other than pointing out a couple of gotchas I ran into. You absolutely need the Arduino 1.8.0 IDE to get this to work, step 4 won’t work with out it. And make sure you set the code configuration.h file, I got black bars the first time around.

After this I downloaded Repetier Host and managed to connect to the printer! I also found a bunch of profiles online that i will link at the bottom. For the record, I also got Simplify 3D to work with this machine if that is what you are using, which has profiles built into it.

Bed Levels

After getting to this point I was still not having luck getting prints to stick to the bed, I manually leveled the bed multiple times ( the custom firmware has more spot to level from ), it wasn’t until the 6th time i was doing it that I realised that the glass bed was warped, all 4 corners were higher than the centre, revealing the problem. So this is where i stopped and said to my mate that he’s best to look out for a heated bed replacement or attempt to repair it

Downloads and Links

Hi Mate i had the same problem until i started using blue or green tape.

You’re still working with it?

I made mine to a pretty reliable ABS machine, still using the original board.

If you’re interested I’d like to share my mods, just mail me.

I need help with my da Vinci 1.0

Can You help me

I know I’m late to the party, but I’ve found Kapton tape to be a game changer. I bought some Kapton tape sheets online, cut one to the same size as the glass bed using a paper cutter, and carefully stuck it to the glass as bubble-free as I could. I haven’t had a single issue with getting prints to stick since!